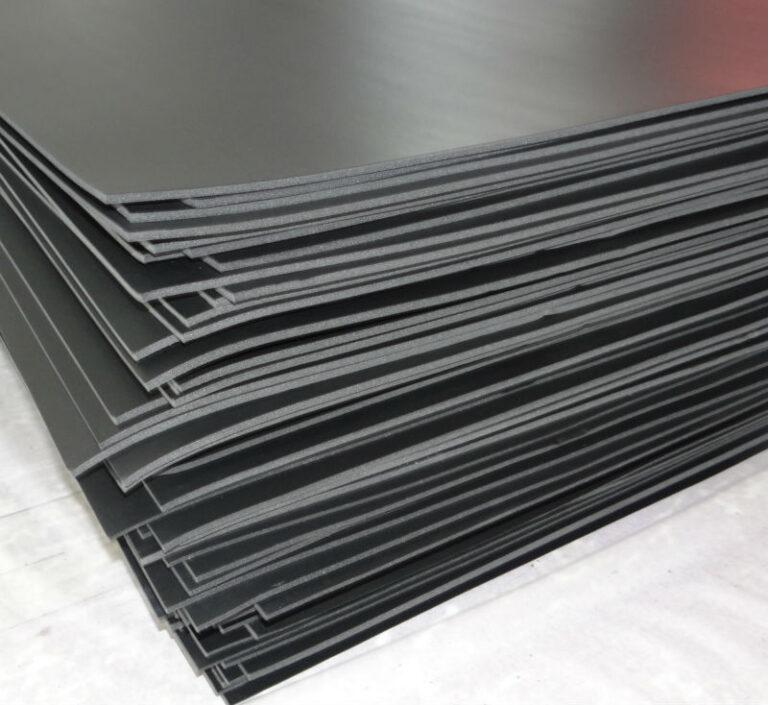

Cross-Linked PE Foam

Chemically or Physically Cross-linked PE (Polyethylene) Rubber or Cross-Linked PE 120-170.

Chemically or Physically Cross-Linked PE foam is a modified foam developed by mixing PE foam with multiple substances in the boiling phase. or re-compressing it under controlled heat and force in order to create a denser and stronger foam. though with the same thickness as the primary PE.

Advantages

Water and non-acidic liquids Resistance, Higher Density with Lighter Weight, Abrasion & Corrosion and Heat Resilience, Shock and Force Resistant

Disadvantages

High Water Absorption Ratio, Harmful for health, Costly.

Specifications

| Units | Specifications |

| Density | 120 to 170 Kg/m3 (Based on Cross-Linking Type) |

| Thickness | 5 mm – 10 mm |

| Width | 1m |

| Length | 1m (Variable in case of rolls) |

Properties

| Item | Value |

| Specific Gravity (Density) | 0.05 |

| Tensile Strength (Kg/cm2) | 4.8 |

| Tear Strength (Kg/cm) | 3.1 |

| Compression Strength (Kg/cm2) | 0.58 |

| Elongation (%) | 140-150 |

| Resiliency (%) | 42 |

| Thermal Conductivity (kcal/mh.c) | 0.035 |

| Shrinkage at 70C (%) | -0.3 |

| Water Absorption (mg/cm2) | 0.1 |

| Heat Resistance Temperature (C) | -100 – +80 |

Please consider that you can order any product within the range of mentioned properties and specifications.

| Product | Price Range |

| Chemically or Physically Cross-Linked PE 120 – 170 Foam Sheets | $12 – $15 Per Default Sheet (1m x 1m) |

| Chemically or Physically Cross-Linked PE 120 – 170 Foam Rolls | $12 – $15 Per Meter |

Cross-Linked PE 120-170: Exemplary Default Foam Product Orders

Please be reminded that the prices of our products are based on the characteristics and properties of your request, the size of your order and the shipping options. The prices of default products are fixed.

A brief description about SBR:

SBR foam (Styrene Butadiene Rubber) is one of the closed cell co-polymer family.

Its similarity to natural rubber makes it a very efficient and effective product in specific occasions.

Additionally, it can be joint with natural rubber materials to make it even more proficient.

The exceptional features of SBR is its flexibility, shock and sound dampening ability, high abrasion resistance and also resisting capably against air, dust and moisture

Advantages

Affordable Replacement for NR, High Water Resistance, Abrasion and Aging Resistance, Flexibility.

Disadvantages

Low Resistance Against Flames, Ozone, Hydrocarbon Solvents and Oil, Difficult Processing Abilities.

Specifications

Cross-Linked PE 120-170 Foam Comprehensive Guide and Applications

The Making Procedure and comprehensive information regarding Cross-Linked PE Foam:

It starts with the manufacturing process of PE foam. The procedure splits into two different cross-linking methods based on the needs of the costumers. that whether they have preference of implementing non-toxic but lower density foam product (still higher than the normal PE). or the chemically cross-linked foam which offers the highest densities possible among all foam or rubber types though at the cost of the product being unhealthy and noxious for almost all living beings.

In the physically cross-linking procedure, the finalized PE foam sheet is pressurized again before cooling under heat and constant pressing. which causes foam molecules to be compressed closer to each other. Therefore, The procedure reduces the thickness of the product. though it is becoming denser than the normal manufactured PE foam with the same dimensions.

The chemically cross-linking procedure does not affect the thickness of the product. Instead, it will fill the gaps between the molecules of polyethylene. making it denser than ever but keeping the weight and dimensions the same. The additive for cross-linking process is Vinyl Acetate. This substance is highly relatable and makes the product softer, stronger and denser.

In comparison with many other foams, Cross-Linked PE is less affordable. The reason is firstly the difficult and highly professional manufacturing process and secondly the density of the products that is higher than the same ranks in the other foam types like EVA, NBR or EPDM.

Most effective applications and Implementations of cross-linked PE 120-170 foam:

- Office or Home Appliances

- Military and Defense

- Electronics Devices (Chemically Cross-Linked)

- Sports and Protective Pads

- Potting and Packaging (Chemically Cross-Linked)

- Medical Purposes

- Construction

- Oil and Petroleum Industry (Chemically Cross-Linked)

The diversity in the applications of cross-linked PE 120-170 foam makes it favorable by many industries. including military, mechanical and civil engineering, electrical purposes, healthcare and medical intentions . and the oil industry where the origin of foam products roots there.

In case of demanding to acknowledge further about the products and their exclusive applications. visit our application page.

Go to the Applications Page