Foam or rubbers are interesting! You can find these practical things everywhere. Just look around to find out how many foams or rubbers can be found in blink of an eye!

For example, the bath sponge is made from foam!

Also, you can find every kind of foam in cars, planes, ships & You can even find every kind of foam in the GYMs.

For example, when you want to do yoga, you must use the yoga mats, yoga rollers, aerobic steps, yoga block and other many things that you can’t even think!

Foams or rubber are used in the critical industries such as oil industry, Astronomy & military industry. That means the foams or rubbers must be reliable and produced in high-end technology.

We have different foam producers in all over the world but some of them are highly experienced & famous in this industry. Germany & China are both great producers & you can buy ever kind of foam from these two!

They are also great exporters and more importantly in the foam industry they are precise & creative.

Also read: Polyethylene Foam Manufacturers (PE Foam)

Foam producers are always looking on their quality & providing the best formula to keep themselves in a breathtaking competition between other serious competitors.

You need to know that all kinds of foams are widely used in every industrial product.

We can also say the foam is a bubbly liquid can be produced by unwanted procedure in all the time of this production system.

foam STRUCTURE

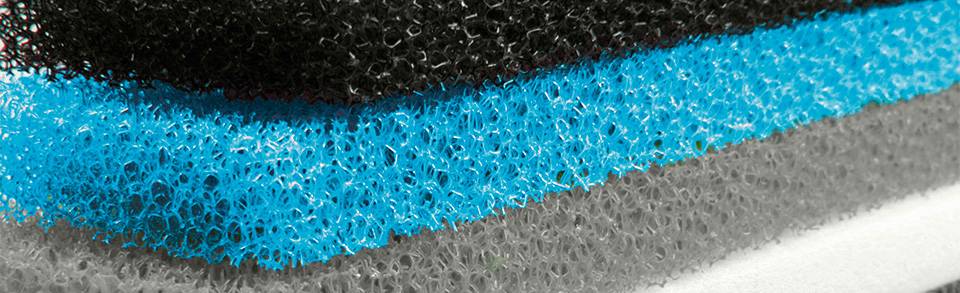

Now we want to speak about the structure of foams. You need to now the foams & rubbers have different structure with multi-scale system.

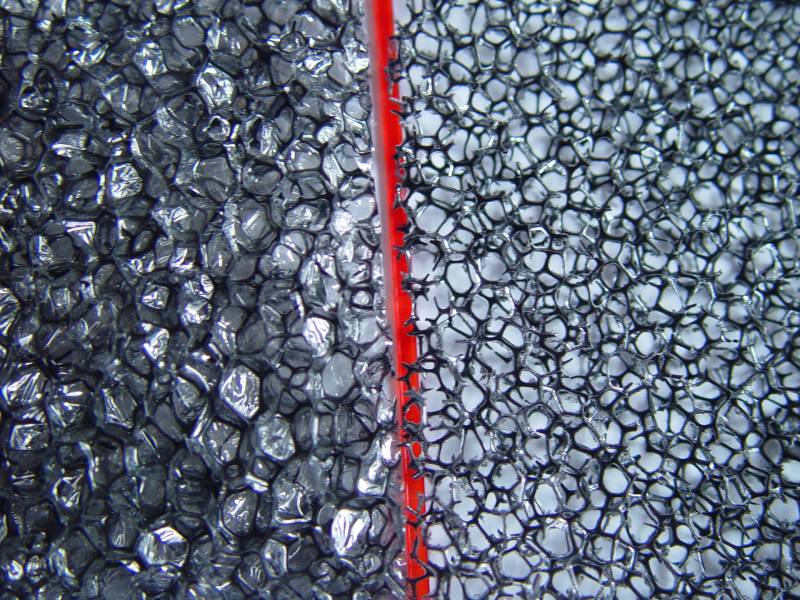

That means one scale is the bubble. You can see the different sizes of bubbles on main structure. In the large size, the bubbles are closely linked together, also you see the mathematically problem of minimal surfaces called “honeycombs”.

In the smaller scales, the linked bubbles are called “lamellae” which is outward from the connection points.

Also, in smaller scales you can see the liquid-air interface on the surface.

In one word, the rubbers or foams is an object formed by trapping pockets of gas in liquid or solid.

If we want to speak about the structure of solid foams or solid rubbers, you must see them structure.

This structure is usually evolving in the fluid of gas bubbles expand to polyhedral cells. You need to know that packed cells have very different scales & sizes.

Foams or rubbers are both examples of dispersed media. In many ways, gas is present, so it divides into gas bubbles of different sizes (i.e., the material is polydisperse separated by liquid zones that may form films, thinner and thinner when the liquid phase drains out of the system films.

When the principal scale is small, i.e., for a very fine foam, this dispersed medium can be considered a type of colloid.

Rubber can also refer to something that is similar to rubber, such as quantum foam, polyurethane foam (foam rubber), polystyrene, XPS foam, phenolic, or many other foams or rubbers manufacturers are examples of dispersed media. Generally, the gas is present, so it separated into gas bubbles of different sizes (also the material is polydisperse).

Separated by liquid regions that may form films, thinner and thinner when the liquid phase drains out of the system films. When the principal scale is small, also for a high-quality foam, this dispersed medium can be considered a type of colloid.

Foam can also refer to something that is similar to foam, like quantum foam, polyurethane foam (foam or rubber), XPS foam, polystyrene, phenolic, or many other foam manufacturers.

The stabilization of a foam is caused by van der Waals forces between the molecules in the foam, electrical double layers created by dipolar surfactants, and the Marangoni effect, which acts as a restoring force to the lamellae.

Many things effect on foam stability. More importantly, we need to select the right surfactants. As mentioned earlier, surfactants are needed to foam bubbles and make the generated foam or rubbers more and more stable.

Also read: How is foam or rubber produced?

Surfactants that are good at foaming may not be good at reducing IFT.

We have several factors that affect foam stability. Foam quality, surfactant types and polymers are some kind of our examples.

One of the most important aspects of foam fracturing is to keep the foam in motion. If the foam is not in motion, it will be unstable. When rubber’s moving has stopped, gravity will cause the free fluid in the foam to drain. This drainage can cause foam more instable.

The rate of foam drainage will depend on many factors, such as temperature, viscosity of the liquid phase, and foaming-agent concentration. The temperature increase can potentially cause a reduction in the viscosity of the fluid.

Now we want to speak about Marangoni effect.

This effect depends on the liquid that is foaming being dirty. Generally, surfactants in the solution decrease the surface tension.

The surfactants also numerous together on the surface and form a layer.

Our Costumers Loves Us

Ready to buy foam? Please Order now.

If you need more information, Please contact us.

Foams: various properties

For the Marangoni effect to happened, the foam must be indented. This indentation increases local surface area. Surfactants have a larger diffusion time than the bulk of the solution.

So, the surfactants are less concentrated in the indentation.

Also, surface stretching makes the surface tension of the indented spot greater than the surrounding area. Consequentially, since diffusion time for the surfactants is large.

The Marangoni effect has time to take place. The difference in surface tension creates a gradient, which instigates fluid flow from areas of lower surface tension to areas of higher surface tension. The second picture shows the film at equilibrium after the Marangoni effect took place.

Being a multiscale system involving many phenomena, and a versatile medium, foam can be studied using many different methods. According to the different sizes & scales, experimental methods are diffraction ones, mainly light scattering methods at sub-micrometer sizes & scales.

According to the system as continuous, its bulk properties can be categorized by light transmittance but also conductimetry. The correlation between structure and bulk is evidenced more accurately by acoustics in particular.

The organization between bubbles has been studied numerically using sequential attempts of evolution of the minimum surface energy either at random (Pott’s model) or you can choose the determination (surface evolver).

The evolution with time can be simulated using these models, or the bubble model (Durian), which according to the motion of every bubbles. You need to know that these specs can be tested again. You also can tell us your experience.

Observations in the structure can be made by shining the foam with laser light or x-ray beams and measuring the reflectivity between bubbles. Observations of the interlocking structure can be done with scattering among the neutron.

Measurement principle of multiple light scattering coupled with vertical scanning.

A typical light distributing (or diffusion) optical methods, multiple light scattering coupled with vertical scanning, is the most widely used technique to monitor the dispersion state of a product, hence identifying and quantifying destabilization phenomena. It works on any concentrated dispersions without dilution, containing rubbers. When light is sent between the sample, it is distributed by the bubbles.

The distribution intensity is directly proportional to the size and volume fraction of the dispersed phase. Therefore, local changes in concentration and global changes in size (ripening, coalescence) are monitored.

Video: Polyurethane Foam - How is it made?

Foams applications

Now we want to speak about the applications of rubbers or foam according to the structures that we spoke about.

When we speak about liquid foam you need to know that we can use the liquid foam as a strong fire retardant.

For example, fire extinguishers are using the liquid foam to extinguish the fire.

The liquid foams having the very unique structure that you can see high specific surface area is exploited in the chemical procedure.

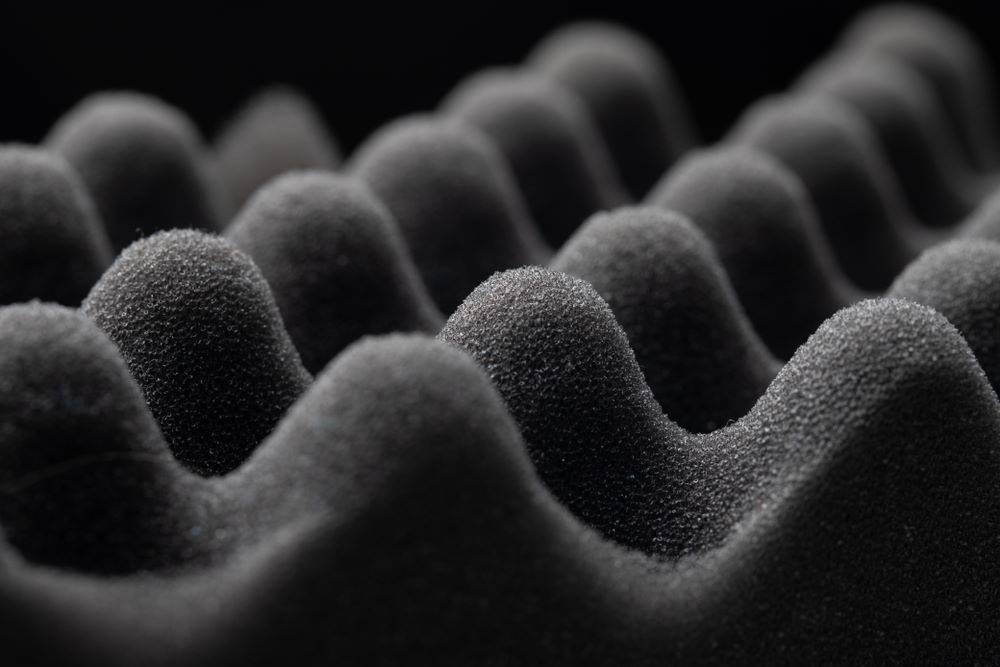

The second class of rubbers is the solid rubbers or solid foams. They are lightweight with engineering cellular material. You need know that foams are mostly classified into the two kinds in their category.

The first one is the Closed-cell foam & the second one is the opened-cell foam.

The opened cells have the holes that are linked to each other with interconnected network that is they are relatively soft.

On the other side, the closed cells don’t have the holes to interconnect to each other. Generally, they have higher compressive strength in their structure.

The closed cells are usually having better moisture absorption, higher dimensional stability & higher strength compared to closed cell foams or rubbers.

We have the special class of closed cell foams named syntactic foam.

Foam, in this case meaning “bubbly liquid”, is also produced as an often-unwanted by-product in the manufacture of various substances.

For example, foam is a serious problem in the chemical industry, especially for biochemical processes.

Many biological substances, for example proteins, easily create foam on agitation or aeration. Foam is a problem because it alters the liquid flow and blocks oxygen transfer from air (thereby preventing microbial respiration in aerobic fermentation processes).

For this reason, anti-foaming agents, like silicone oils, are added to prevent these problems. Chemical methods of foam control are not always desired with respect to the problems (i.e., contamination, reduction of mass transfer) they may cause especially in food and pharmaceutical industries, where the product quality is of great importance.

Mechanical methods to prevent foam formation are more common than chemical ones.

The most famous foam suppliers in the world

What is foam faq

1. What is foam material

Foam or rubber (also known as cellular, sponge, or expanded rubber) refers to rubber that has been manufactured with a foaming agent to create an air-filled matrix structure. Commercial foam rubbers are generally made of either polyurethane or natural latex.

2. What is foam in chemistry?

Summary. A foam is a dispersion of a gas in a liquid prepared using a foaming agent, which in most cases consists of one or more surfactants. Foams can be prepared from two overall processes termed condensation and dispersion. This chapter discusses some applications of foam structures.

3. How is foam manufactured?

Foams are made by forming gas bubbles in a plastic mixture, with the use of a blowing agent. Foam manufacture is either a continuous process for making laminate or slab stock or a batch process for making various shapes by cutting or molding. There are two basic types of foam.

4. Is foam toxic?

According to the United States Environmental Protection Agency (USEPA), exposure to some of the main ingredients of polyurethane foam – isocyanates – can cause a range of negative health effects, including asthma, lung damage and respiratory problems and damage and skin and eye irritation.

5. Can foam rubber be recycled?

Foams and mattresses can all be recycled effectively. ... Foam: Foam, wadding and latex from inside the mattress is recycled into carpet underlay.