- +90-544-774-1416

- info@hongkongfoam.com

We know that rubber is produced by trapping millions of gas bubbles in a liquid or a solid piece. Whisking water and air produces hundreds of bubbles & leaving only water and air over & over again. We have a great procedure in foam or rubber production, the Polymerization! This part of production rates for … How is foam made? foam rubber manufacturing

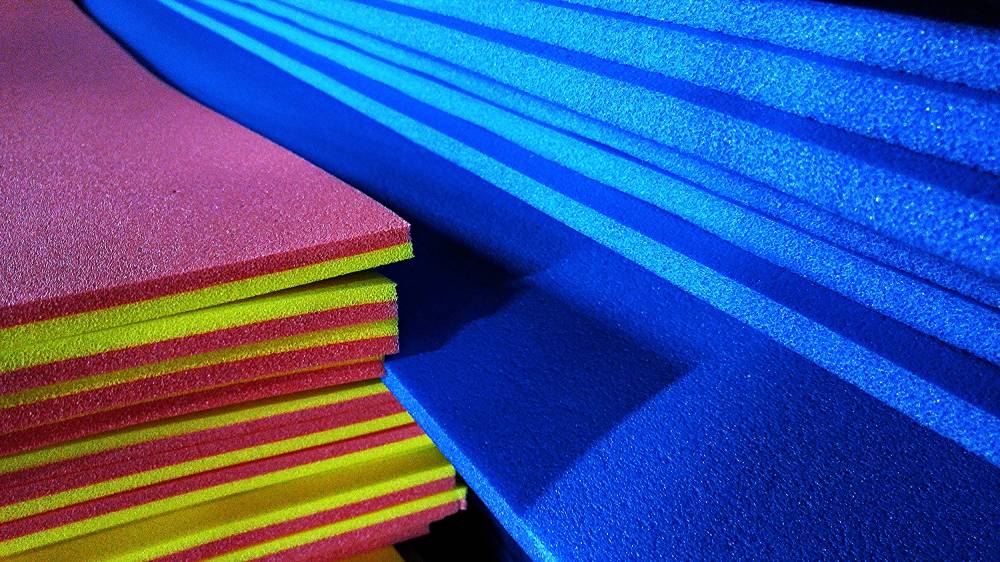

With foam being the very core of every cushion project, it’s important to choose the right one for your application. Different types of foam have been engineered to float, drain water, prevent mold, and mildew, and withstand daily wear. You want to choose foam with attributes that are compatible with the way you plan to … Foam Series: Comparing Types of Cushion Foam