closed cell vs open cell foam

Heat insulation & insulation for vapors, noises, and other elements has an alternative! The foam!

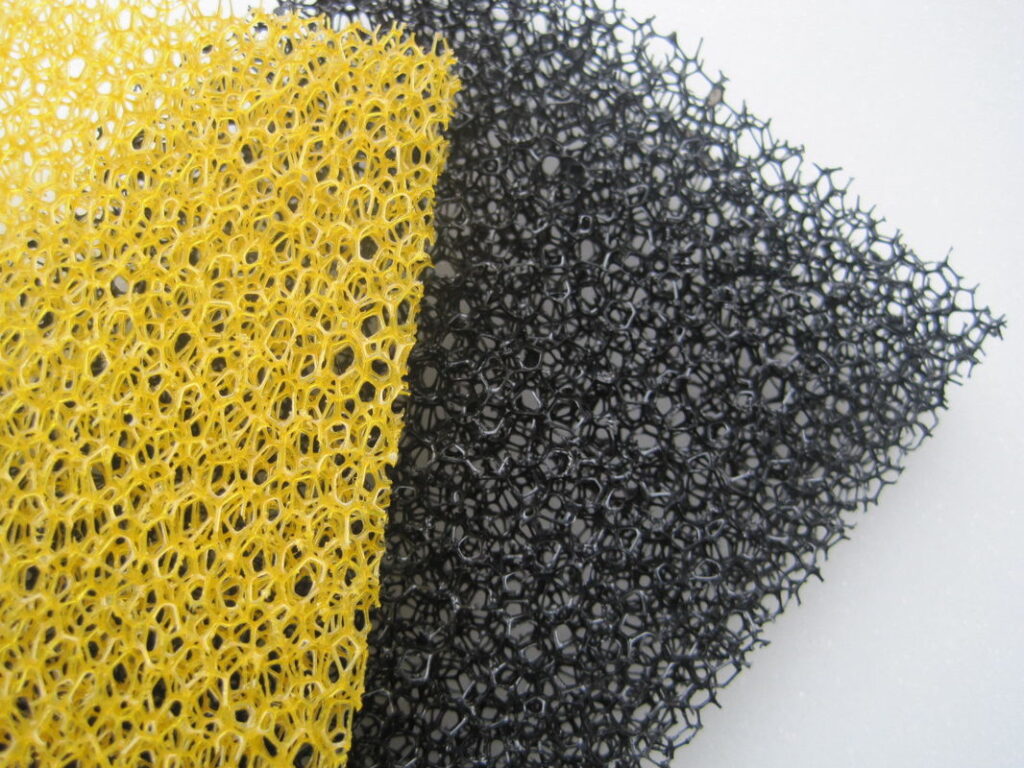

We have two kind of foam, the first one is open cells and the second one is closed cells. Both kind of these are used in daily application & products, but because for different structures, one of these is much better than any other kind of foams.

You need to know that every kind of rubber or foam is created by gas under a very high pressure into a polymer while it is in a liquid state, causing the formation of thousands of tiny bubbles that they are in the polymer.

Every kind of rubber has a different structure and permeability and behaves differently depending on your application.

We have many reasons to choose between the closed cell & open cell. The main difference that cause manufacturers to select between close and open cell foam are their permeability to different elements, that means how effective they are & how reliable they are.

If you want to see the comparison between open cell and closed cell foam, See this article completely.

Open cell foam v closed cell foam.

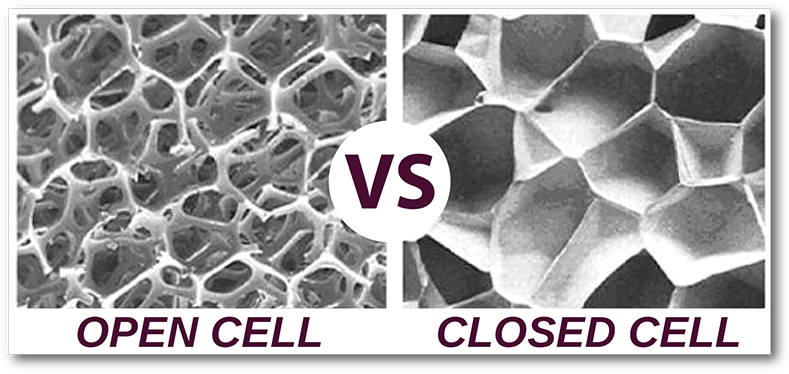

When we talk about the closed cell foam, you need yo know that the cells are like tiny air piled together in a compact space, resembling inflated like balloons nestled tightly to each other.

The close cell pack, closed cell rubber is vapor semi-impermeable, more rigid, able to withstand greater pressure, and amazingly is about 4 times denser than the other kind that we called the open cell foam.

Open cell foam

You need to know that the manufacturing of open cell foam has the same procedure for closed cell foam. Also, open cell foam is designated to be vapor permeable as the structure of the cells in the material, rather than closed.

They are both have the holes inside a sponge, air can penetrate to the open cells easily, making open cell foam more holes and absorbent than the other kind of

You need to know that the closed cells are a better air barrier than open cells. The closed cells can be used to airflow controls as it is less penetrating.

You can produce the premium & reliable gaskets & seal with closed cell foam. On the other hand, the open cells are a better for producing filters than closed cells because it permits to pass the air.

The Open cells makes an appropriate air filter for engines because it can gather dust and pollutants but not restrict air flow.

Is closed cell foam waterproof?

You can rely on the waterproof functionality than open cells. Closed cell is more practical than open cell foam. Closed cell foam has low penetration to water, vapor, and air. Therefore, it is less likely to be structurally impacted by the effects associated with water damage, bacteria, mildew, mold, rot.

You need to know that the closed cell foam which can lead to lowered performance, especially for thermal applications.

While engineers do not necessarily strive for perfect vapor impermeability, the free flow of water can be detrimental to a structure and can trap water.

When environment is moist, closed cell foam is a better option to use with as it’s less likely to absorb water and become an ineffective insulator.

Closed cells are more reasonable for wrapping a water tank than open cells.

Closed cells & open cells are very good heat insulation.

We know that one of these two might perform better than the other one, amazingly if the environment is moist. Open cells are not a good insulation against humid.

An opened cell foam will not retain or deflect heat effectively. It is also a poor insulator against water.

When we talk about sound proofing, the open cell foam performs a better performance against closed cell foam. You need to know that the open cells structure allows the noise or sound waves to interact with residual membranes so that the energy is transformed into heat, absorbing some of the noises & sounds.

Cost comparison

You need to know that the opened cells are more cost effective than the closed cells. It is also cheaper to achieve the same thermal insulation from open cell foam because it has less plastics than the other one.

Also, the air within the open cells plays an important role as a great insulator.

When you choosing between closed cells & open cells, the price is a concern that impacts the decision of technicians and producers just as much as the properties of a particular rubbers.

You need to choose the right foam for your industry. You can also ask every question you want.

Closed cells are impermeable and lowered the air & the flow and is less water absorbent, while the open cells are permeable and air and water can pass through it. Depending on your conditions, one of these is a better barrier than the other one.

At the end, please feel free to contact with us.

Our Costumers Loves Us

Ready to buy foam? Please Order now.

If you need more information, Please contact us.

Material Cost

The Open cell rubber mostly bring in a price of material in use. The most common open cell foam is PE foam and artificial PE foam.

Thanks to the cost-effective material, they have been mostly used for furniture & home appliances, seat cushion, carpets & filters that they are made with foam.

You need to know that the closed cell foam mostly shows better performance on insulation and durability, it is also transformed to a higher material

We have a lot of uses for the closed cell foam. They can be quite helpful for a different use which needs shock & moisture resistance.

It is also a very good heat & sound insulation. The closed cell material as well as the sponge products are very common with the insulation, cushioning, padding and gasketing uses for many years. The uses of closed cell foam are unqualified.

You can customize your own foam to protect your pricey things like jewelry, tools and electronics etc. They provide excellent cushioning for protection, moisture and air resistance as well, which prohibited the moisture from collecting inside the package, making it the best alternative for safely storing gentle machinery for longer period of time.

The general applications for closed cell foam include:

- Insulation and sealing for construction and building

- The appliances and HVAC system

- Thermal insulation and shock absorption

- The seals of enclosure and cabinets

- The medical disposables

- The equipment of gas and oil

- Aerospace and aircraft

- The transportation and automotive

COMPARISON BETWEEN OPEN CELL FOAM & CLOSED CELL FOAM

Foam materials are a kind of cellular product. The structure of its cell and especially the contents of its cells, whether open or closed, will have a significant influence on the performance of the product and its final applications.

Although open cell foam and closed cell foam may present similar appearances, they should be treated as two different products as their properties and performance are totally different.

When you want to distinguish closed cell foam from open cell foam, you can take another quick and smart method. It is simple and easy by just pouring some amount of water on both types of foam materials.

You can suddenly find out one type of foam absorb water and take water inside the tiny cells. But the rest one do not absorb water and keep water out from their surface. So now you might know the first one is open cell foam and the rest one is closed cell foam.

The voids in the open cell foam intersect each other, forming paths through the solid. Closed cell foam consists of individual closed areas, so air or liquid cannot penetrate this type of foam.

They have different performance in face of moisture, water, air and other liquid due to their foam structures.

Custom Cutting Open Cell Foam

Open cell foams are generally soft and compressible. Foams with open cells act as good insulating entrapment of air inside the cells. Foams with open cells, like a sponge dish brush are able to absorb the liquid in their cells.

Closed cell foams can provide greater structural rigidity, and because the cells are closed, the cells can be filled with gases other than air during manufacturing.

Closed cell foams can be used to prevent water or air from moving from one area to another. Also, open cell foam is often used for its absorption qualities, particularly for sponges.

Open cell foam is also used in a variety of insulation uses because of its low-cost value. Open cell foam can also be used for sound dampers, shock absorbers, cushioning and pillows.

Closed cell foam is often used in flotation devices, since its closed cell structure does not absorb water and trapped air is energetic.

And Closed cell foam is often used in other uses that require water resistance, such as neoprene suits, mats, gaskets and insulation. It is denser than open cell foam and generally more expensive to produce.

Difference Between Open-Cell and Closed-Cell Foam

If you are new to the wide world of foam, you may have a few questions regarding the difference between open cell and closed cell foam. While both types are available for a range of applications, it a good idea to have a better understanding of the differences between the two to ensure you get the option that is best suited to your particular needs.

Let’s take a closer look at the major difference between open cell and closed cell foam.

The big difference between these two types of foam is clear.

One option has cells that are closed and one has cells that are open. However, most people are left wondering what that actually means.

Open cell foam has tiny cells which are not completely closed. The open cells are filled with air and this affects the way the foam feels and performs. Closed cell foam has cells which are sealed off so air doesn’t get inside the structure at all.

The major difference between the two foam options is that closed cell foam tends to be harder or firmer while open cell foam is softer or less firm.

Another difference is that closed cell tends to be less springy with soft cell foam offering more spring to it. It should be noted that for foam to receive an open cell distinction not all cells must be open.

A foam material can have an equal ratio of closed and open cell and it will automatically be classified as open cell. However, this type of half and half ratio usually means the foam is still softer than fully closed cell foam, but harder than a foam with all the cells entirely open.

There are several uses for foam with one or other type of cell structures being more ideal. For example, since closed cell is incapable of holding water to make a cushion heavier and harder to dry out, it is often used in outdoor cushions.

Closed cell is also used for various purposes where a sturdier structure is needed such as packaging and shipping needs, protection barriers, and more. Since closed cell is harder and has less give to it, it is ideal for purposes requiring added stability such as transporting breakable items from one location to another.

This type of foam can be used in construction as building insulation since it creates a nice barrier to trap heat and air conditioning inside a building to reduce utility costs. It can also be used for certain electrical and automotive applications as long as it stays clear of heat.

Open cell foam definitely has its uses, too. Softer and springier, this foam type offers superior comfort and support for a range of applications.

While clear solutions include cushions for residential seating such as sofas and chairs, foam fill sacks, commercial uses ranging from car seat manufacturing to mattresses, and much more, this type of foam can be used for a range of solutions.

Also read: How do you make foam?

With the better comfort it offers, it is no wonder open cell is used in all manner of sofas, chairs, loveseats, and mattresses. Available in varying levels of firmness and density, open cell foam can be super soft or firmer for more support. It can be used in support aids, pillows, pet beds, and much more.

When looking at the durability factor, there are very few differences between the two. While closed cell foam is generally stronger and longer lasting than open cell foam, both options offer lasting durability. Closed cell is tougher since it provides improved rigidity.

It is also tougher in terms of rips or tears whereas open cell foam is more vulnerable to surface damage.

Many people think that the cell structure of the foam is related to thickness variations. However, both open and closed cell foam are available in varying degrees of thickness.

The thickness needed will depend on the application. While both types of foam structures can be used in varying thicknesses, open cell foam can lose the springy nature of the material when used in options too thick, and closed cell can be less sturdy in thinner cuts as opposed to thicker ones.

When choosing between the two, the types of applications, as well as the desired results, will be the main determining factor in which type is more suitable. Both options are known to offer the lasting endurance and high levels of performance expected of this versatile material.

FAQ: (Frequently Asked Questions)

What is closed cell foam used for?

Closed cell foams are the most popular type of insulation used in remodeling and new construction applications. They can provide support to the structure due to the composition of their cells. They protect against water damage, and generally provide a higher R-value per inch than open cell foams.

Will closed cell foam absorb water?

Closed cell foams also do not absorb water, which is very beneficial in flooding zones. In fact, because it is water resistant, it is often used as an effective repair for leaky basements.

What's the difference between open and closed cell foam?

Open cell foam is full of cells that aren't completely encapsulated. In other words, the cells are deliberately left open. This makes the foam a softer, more flexible material. Closed cell foam is made up of cells that are, as the name suggests, completely closed.

Does closed cell foam need a vapor barrier?

Icynene spray foam insulation controls air leakage so effectively that a separate vapor retarder is often not necessary. In fact, when a commercial building code requires it, all of Icynene's closed-cell, medium density, spray foam insulation officially qualifies as a class II vapor retarder.

Will closed cell foam kill mold?

Closed cell foam will kill mold. Molds cannot survive the exothermic heat and the ensuing encapsulation.